Introduction:

Automotive gasoline one of the refinery’s main products. In the last few years, it has undergone significant specification changes meant to reduce pollutants emissions, improve burning efficiency and secure quality by preventing adulterations.

In addition to these changes, escalation in refineries’ complexity introduces the possibility of adding new process streams to the gasoline blend as they become available. Each kind of process stream contributes to different features that will influence the quality of the finished motor gasoline.

This work will address the most common gasoline blend components and some of their properties, mainly focusing on the most usual limiting factors: octane and sulfur.

Gasoline blend:

Generally, automotive gasoline is made of a mixture of naphtha range streams and one or more oxygenated additives, the type and amount of which will vary according to the country. In South America the most common oxygenated additive is anhydrous ethanol, of mandatory addition in a few countries; the use of ethers, mainly MTBE, is also practiced wherever allowed. Such additives influence the finished gasoline’s octane, its specification usually referring to octane after being admixed with them. In many countries additivation occurs out of the refineries.

In refineries the gasoline blend is usually performed in final product tanks, with pre-specified amounts of each of the components, based mainly on their sulfur content and octane. Other specifications, such as vapor pressure, for example, should also be taken into consideration for preparing the recipe.

Octane:

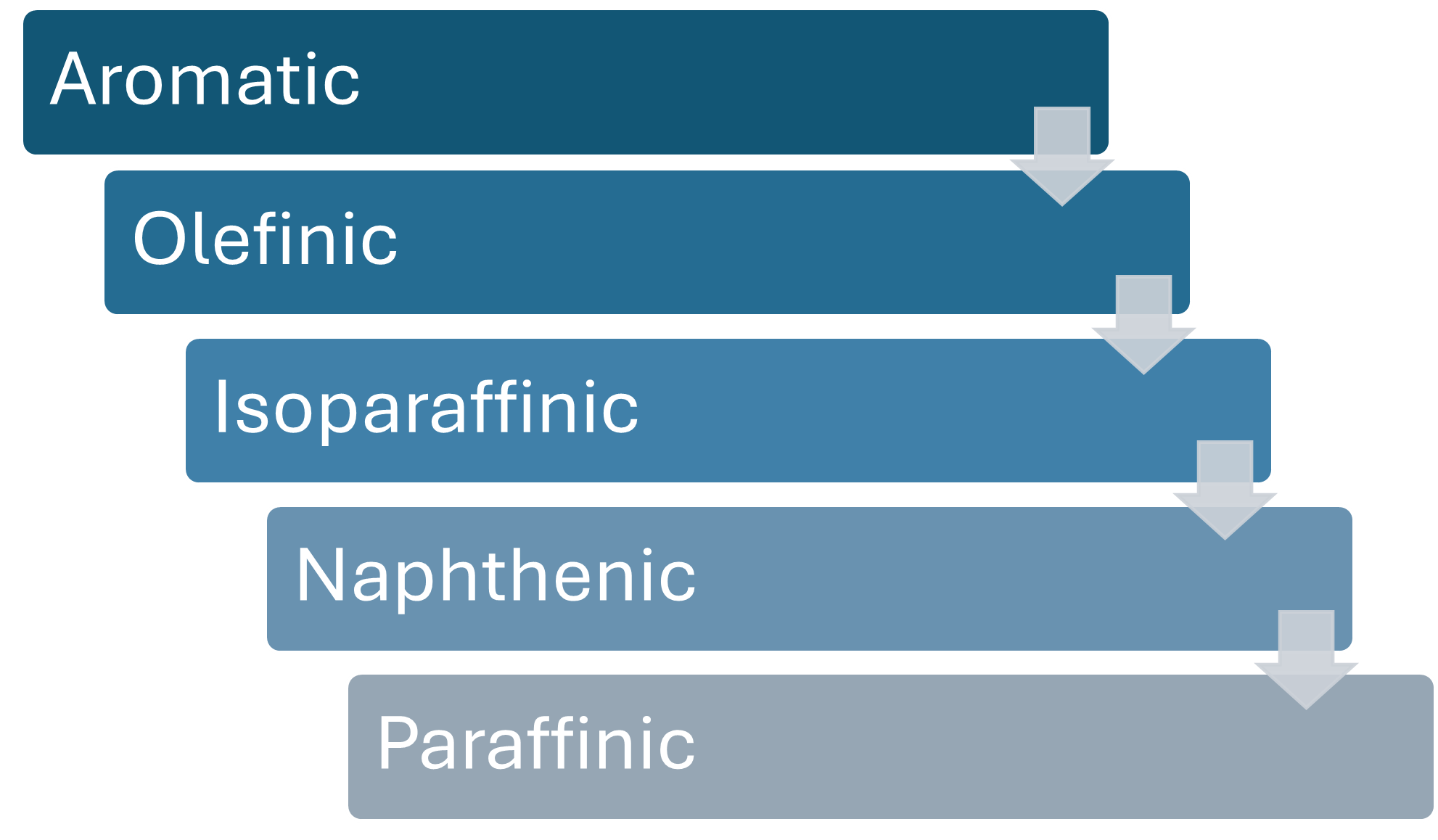

Naphtha’s octane depends on the kinds of hydrocarbons present. Generally, it varies with the hydrocarbon types in the following order, from high to low:

Figure 1. Hidrocarbons’ octane

For hydrocarbons of the same kind, the higher the carbon number the lower the octane. Remember that zero octane corresponds to n-heptane and 100 to iso-octane, so it is possible for hydrocarbons to have lower-than-zero and above 100 octane.

For more information on octane number, see the Technical Moment edition – Experts’ Hints on Automotive Gasoline.

The kinds of hydrocarbons in each process stream that is used in gasoline lead to changes in the finished blend’s octane. For paraffin-rich streams, the tendency is to reduce the blend’s octane , while an aromatic, olefinic and branched compounds-rich naphtha tends to increase octane . Understanding the type of hydrocarbons in each stream incorporated to the gasoline blend is essential to predict its impacts on the product, since octane is a hard to model property, with complex mixing rules, especially when oxygenated compounds incorporation is considered.

Sulfur:

In most of South America there is a movement for reducing gasoline’s maximum sulfur content, which may limit some naphtha’s incorporation to the gasoline blend. To adjust to legislation changes, many refineries started to hydrotreat the higher-sulfur-containing streams to maximize their incorporation to the blend, while other ones had to make changes in crude oil diet and fractionation adjustments to adapt. Having mass additivity, it is quite simple to accurately calculate the final gasoline sulfur based on the blend components properties.

Generally, the sulfur content in gasoline streams increases as their final boiling points increase, the sulfur concentration for each temperature range varying according to each naphtha’s origin. That is why, if no hydrotreating units are available, it may be necessary to reduce the final boiling points of gasoline-directed streams, which lowers the refinery gasoline output.

In case of extensive olefins saturation, naphtha hydrotreatment for sulfur adjustment can negatively affect the naphtha streams’ octane.

Main stream types used in gasoline blends:

- Natural gasoline: this is the naphtha range stream obtained in natural gas processing units, also known as condensate. Rich in low density linear paraffinic compounds, it usually reduces the finished gasoline's octane because of its very low octane. Its sulfur content varies according to the gas field from which it was extracted.

- Direct distillation naphtha: this is naphtha obtained in crude atmospheric distillation units. Its octane number and sulfur content depend on the petroleum selection, but compared with other refinery streams its octane, as well as its sulfur content, is low. The more paraffinic the crude, the lower the direct distillation naphtha octane.

- Cracked naphtha: it is obtained through fluidized catalytic cracking; the high olefinic (with contentes that can be higher than 40%) and aromatic compounds content renders it a high- octane stream, but many times it cannot be marketed by itself as gasoline because it exceeds these compounds limits. This naphtha’s high sulfur content also limits its incorporation into gasoline unless it is hydrotreated. Because it contains diolefins and mercaptan compounds, in case it is not hydrotreated it also requires sweetening treatments and antioxidants addition.

- Coke naphtha: originated from the delayed coking unit, when untreated this naphtha is high in diolefins, which makes it very unstable, as well as high in contaminants such as sulfur and nitrogen, so it is mandatory to hydrotreat this stream before incorporating it to the gasoline blend in units prepared to receive a diolefin-rich feed. After hydrotreatment coke naphtha has intermediate octane number.

- Reformate: The naphtha obtained through the catalytic reforming process has a high concentration of aromatic compounds and very high octane, while sulfur content is practically null. It is a highly valued naphtha used to increase the blend’s octane, enabling the incorporation of low-octane streams, or for the production of special gasolines. Its incorporation to the gasoline blend is generally limited by the maximum allowed aromatics content.

- Alkylate: naphtha obtained through the process of olefins alkylation is rich in branched compounds, particularly isooctane, and has very high octane. As it is produced from treated LPG it has low sulfur content and presents as a good alternative for refiners that have high olefinic LPG production. It is a highly valued naphtha used to increase the the gasoline blend’s octane and for special gasolines production.

- Isomerized naphtha: the isomerization process transforms normal paraffinic compounds into high-octane branched compounds, enabling isomerized naphtha to be used for increasing the gasoline blend’s octane and for producing special gasolines. In addition, as it is very low in sulfur, it contributes to allow the incorporation of higher sulfur content streams to the blend.

- Butane: despite being a linear paraffinic, due to its short chain butane has high octane (RON 94) and can be incorporated into the gasoline blend as an alternative to increase this product's added value in refineries with surplus LPG production. The limitation to its incorporation to the gasoline blend is the maximum vapor pressure and it is a good alternative for colder locations, where this limit is normally higher.

- BTEX and other aromatics: aromatic streams such as benzene, toluene, ethylbenzene, xylene and isopropylbenzene are very high in octane, low-sulfur streams. When observed the aromatics content limits in gasoline, those streams can be used for increasing the blend’s octane.

- Raffinate from aromatics extraction and other light paraffin streams: these are naphtha range, very low-octane and low-sulfur streams, their incorporation into gasoline being limited by octane.

Every refinery has its peculiarities and each stream with a potential for incorporation into the gasoline blend has unique characteristics which should be considered in the context of this refinery.

The experience of FCC S.A.’s technical services team can help you optimize your gasoline blend, contact us!

What did you make of the publication?