Introduction

In the oil and gas industry, oil reservoirs can be classified into two main categories: conventional and unconventional. Unconventional oil reservoirs have specific geological characteristics, such as low permeability and rapid pressure drop, which require stimulation to produce hydrocarbons. They also exhibit a significantly lower oil recovery compared to conventional reservoirs.

The development of the oil and gas industry has been marked by the increasing exploration of unconventional reservoirs, driven by the need to meet global energy demand. As conventional oil resources become progressively scarcer or economically unfeasible, attention turns to sources such as shale and tight oil, and, in the case of Brazil, the pre-salt. These resources present specific technological and operational challenges, derived from the characteristics of geological formations, such as low permeability, high heterogeneity, and the presence of contaminants that directly impact the efficiency of production and refining processes.

Production from unconventional crude reservoirs requires the use of advanced drilling, completion, and stimulation techniques, such as hydraulic fracturing and horizontal drilling, to economically enable hydrocarbon extraction. Furthermore, the refining of these streams imposes additional requirements on the catalytic systems of fluidized catalytic cracking units (FCCU), which demands the development of more robust catalysts and operational strategies capable of mitigating the adverse effects caused by contaminants such as iron, calcium, copper, sodium, potassium, among others, as well as by other inherent feed characteristics (such as higher acidity, oxygen content, and the presence of salts).

1. Shale oil

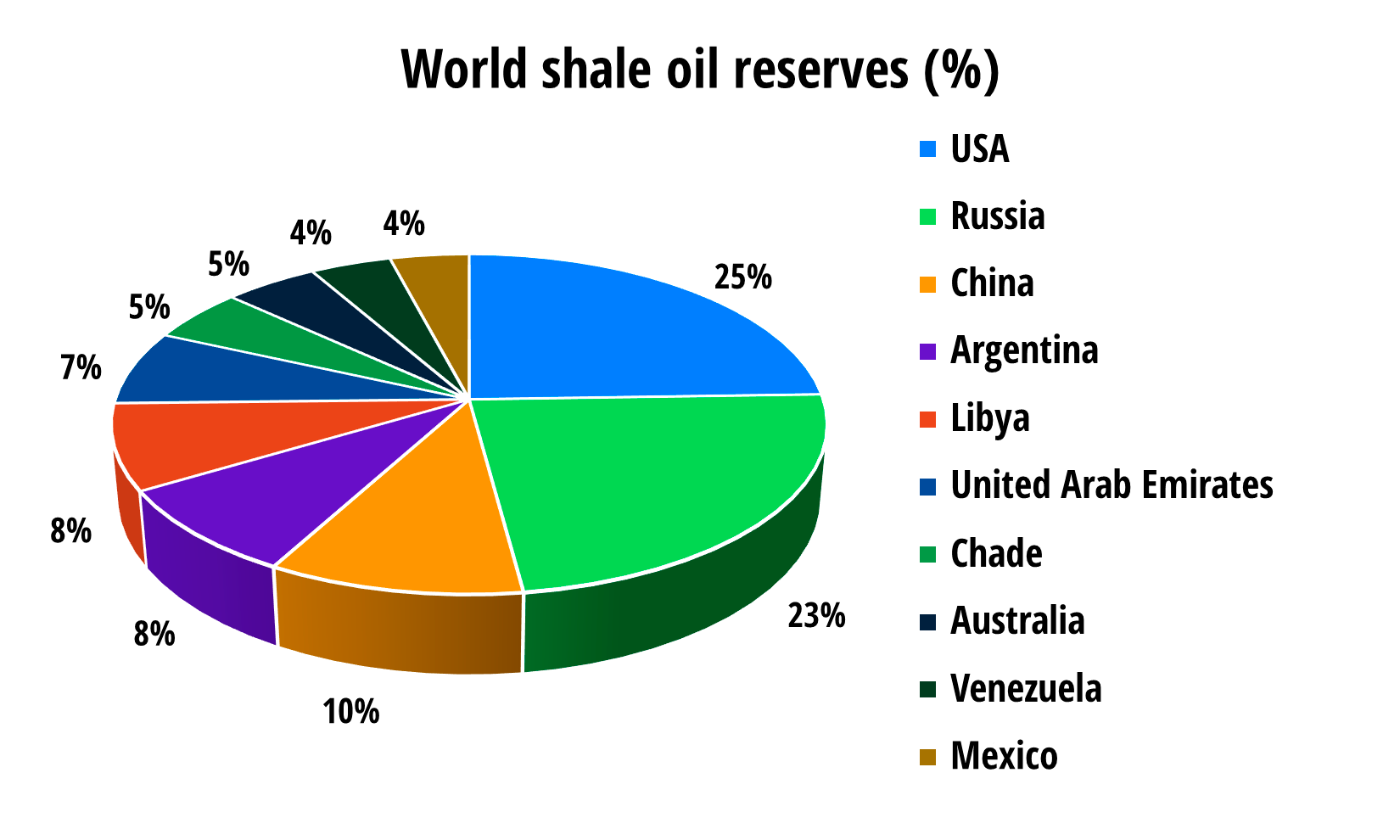

Shale oil is considered the most valuable unconventional oil with the greatest development potential. The production of shale oil in the United States has triggered a revolution in the global energy landscape, rapidly increasing the country's oil output. In China, geological reserves of shale oil are estimated at about 30 billion barrels, representing significant development potential. Another country that stands out for its large shale oil reserves is Argentina, particularly in the region known as Vaca Muerta. In 2013, the U.S. Energy Information Administration (EIA) estimated that the recoverable oil volume in Vaca Muerta would be around 16.2 billion barrels, positioning Argentina as the fourth country with the largest unconventional oil reserves in the world.

Figure 1 – Global shale oil reserves.

Source – Adapted from EIA, 2025.

Shale oil is composed of oil preserved in organic-rich shale and exhibits medium to high levels of organic maturity. Shale acts both as a source rock and as a reservoir rock and can therefore be referred to as "generative rock oil”. Shale oil exists in adsorbed and free states, and it generally has low density and viscosity. It is primarily stored in pores and nanoscale fractures, distributed along lamellar strata or parallel microfractures. Table 1 presents some characteristics of the main shale oil exploration sites around the world.

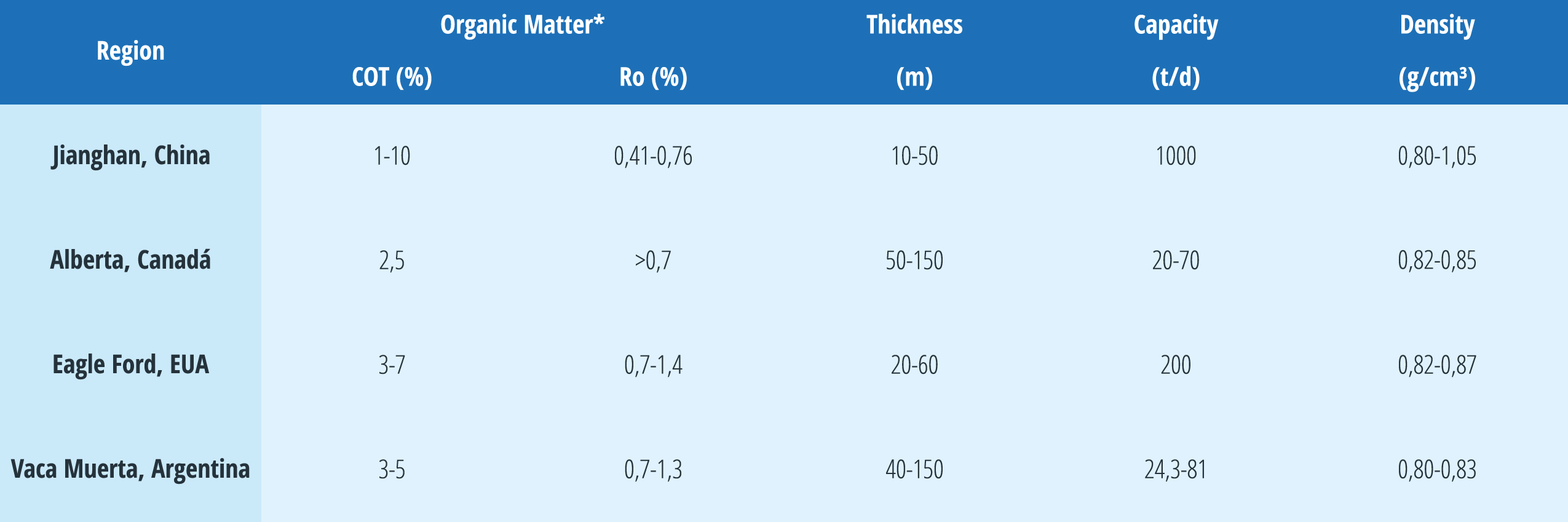

Table 1 – Properties of some important shale oil exploration points in the world.

Source – Adapted from WANG et al., 2019.

2. Tight oil

Tight oil is conventional oil found in reservoirs with low permeability (less than 0.1 mD) and low porosity (less than 10%), which require technologically advanced drilling and completion techniques. The extraction process results in liquid hydrocarbons obtained through hydraulic fracturing of shale formations, leaving a heavy fraction, similar to tar, within the shale deposit.

The largest technically recoverable reserves of tight oil are located in Russia (75 billion barrels) and the United States (58 billion barrels), while China, Argentina, Libya, Venezuela, and Mexico also standing out, which together total 30 billion barrels, according to EIA data.

In general, the composition of tight oil is different from traditional oils, exhibiting:

- higher API gravity;

- higher yield of diesel and light fractions;

- higher contamination by Fe, Ca, Na, and Pb;

- lower sulfur content;

- higher paraffinic content.

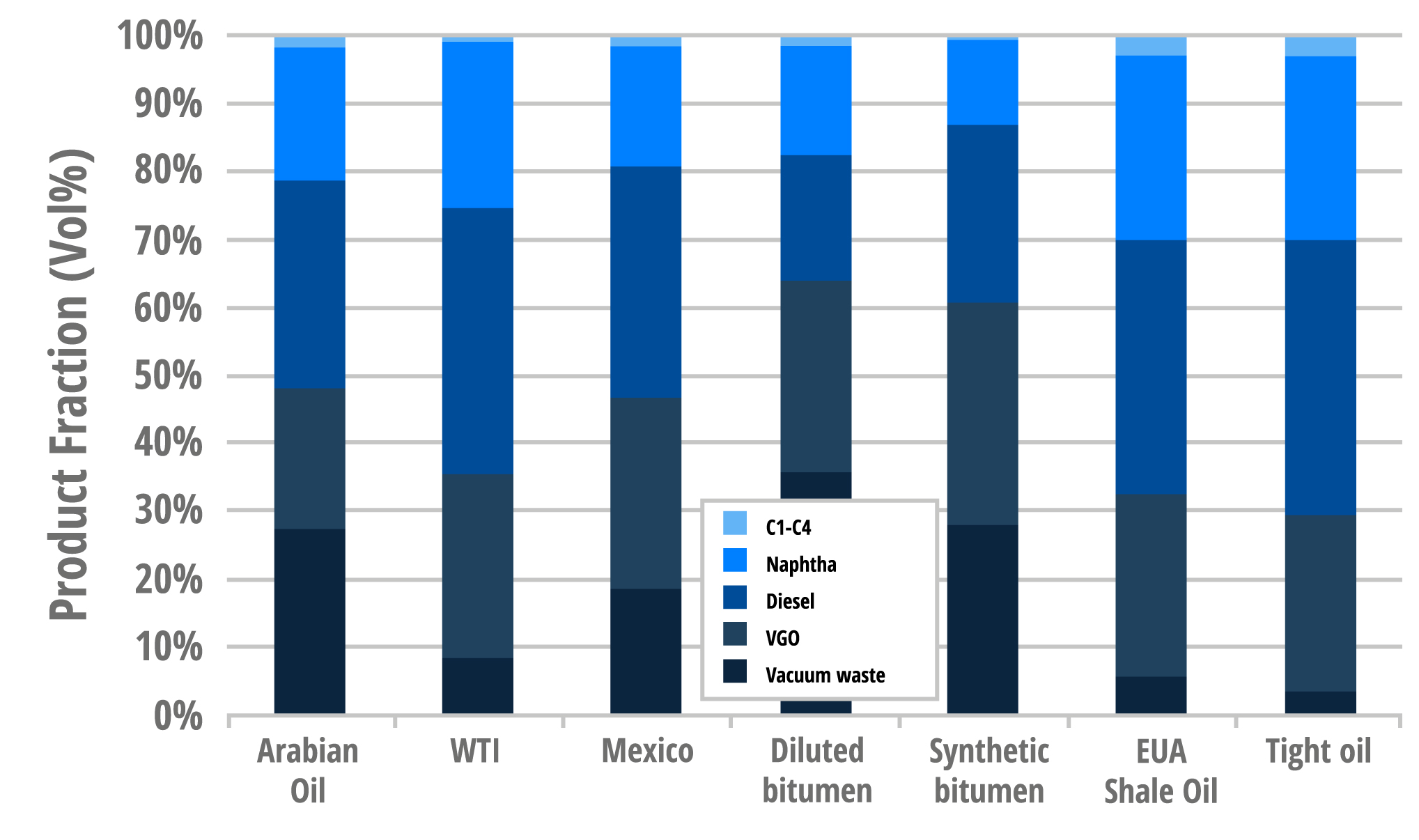

Due to the difference in product yields compared with traditional crudes, as illustrated in Figure 2, it may be necessary to blend tight oil with other crudes to adjust yields or to adapt processing units, particularly in older refineries.

Figure 2 – Comparison between tight oil and other unconventional oils.

Source – Adapted from LELIVELD and TOSHIMA, 2015.

3. Pre-salt oil

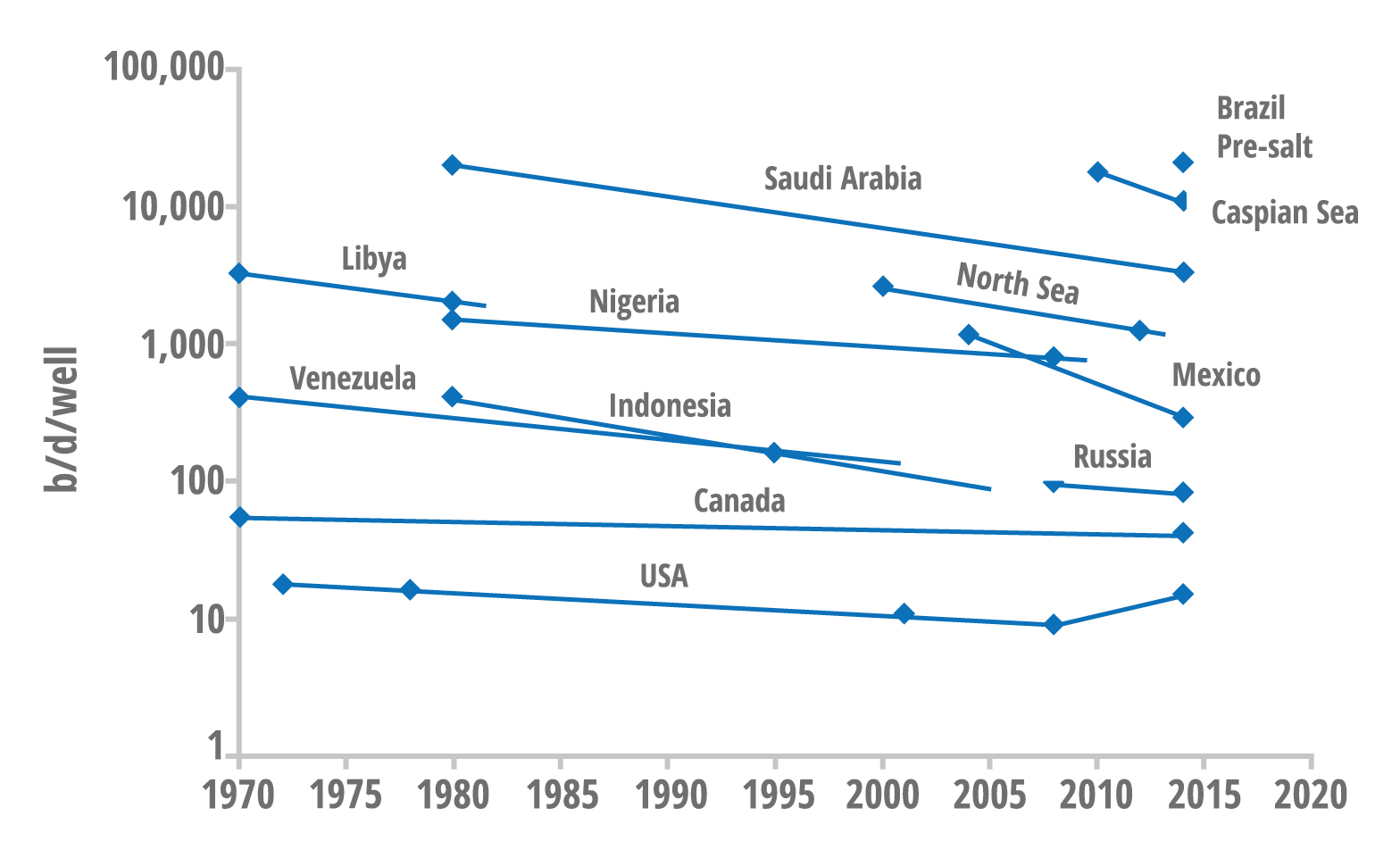

Pre-salt oil was discovered in Brazil in 2007 and is found in sedimentary rocks located beneath a thick salt layer, up to 2,000 meters, which acts as a barrier preventing oil migration. Daily oil production from the pre-salt fields is remarkably high, having increased from an average of 41,000 barrels per day in 2010 to around 1.9 million barrels per day in 2020, with projections indicating it could reach 5 million barrels per day by 2030. This growth demonstrates the exceptional productivity of pre-salt wells, as shown in Figure 3.

Figure 3 – Productivity of oil wells in various regions of the world.

Source – SANDREA and GODDARD, 2016.

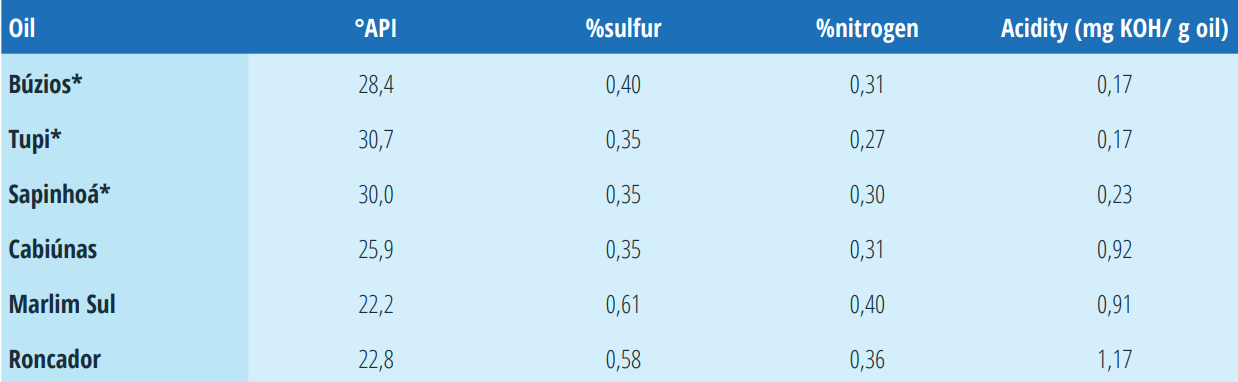

According to the National Agency of Petroleum (ANP), pre-salt oil is classified as light crude because it has a higher API gravity compared to other types of oil. In addition, the extracted oil contains lower sulfur content but higher levels of sodium, calcium, and potassium salts. These salts are a source of corrosion for refinery equipment. Table 2 presents a comparison of the characteristics of pre-salt and post-salt crude oils.

Table 2 – Comparison between Brazilian pre-salt and post-salt oils.

Source – Adapted from DELGADO and GAUTO, 2021.

4. Challenges for refining

Each refinery unit is designed according to the expected average quality of the feedstock, with a margin that allows for some operational flexibility within a specified range. Among all units, the distillation unit is the most sensitive to feed quality, while the downstream units are generally affected by the flow rate and the quality of the distillation products.

When processing unconventional crude feeds, paraffin depositions can occur in pipelines, increasing pressure losses in the systems and potentially posing a particularly serious problem for the lines that supply refineries.

Due to specific characteristics such as the presence of suspended solids and the high pour point, processing lighter feeds may require investments in tank and pipeline heating systems, as well as adjustments to pump filters.

Generally, two strategies are employed:

- Mixing crudes to adjust product yields and quality according to the refinery's configuration.

- Modifying process units to accommodate the new feed and performance profile.

The blending of these oils with conventional crudes, which contain higher levels of heavy hydrocarbons, can exacerbate certain well-known operational issues. In the context of product yield and quality adjustment, blending light crudes with heavier ones is a logical and widely adopted practice.

However, even when there is an intention to initially segregate these lighter crudes, such as in intermediate bases and reception tanks, the storage system’s configuration may lead to unintentional mixing due to the presence of slopes in the tanks. This mixture of light and paraffinic crudes with heavier crude oils, whether intentional or not, can result in asphaltene deposition, a phenomenon that indicates crude oil incompatibility. In this context, laboratory analyses performed prior to cargo reception can help predict and mitigate this problem, as well as the use of specialized software.

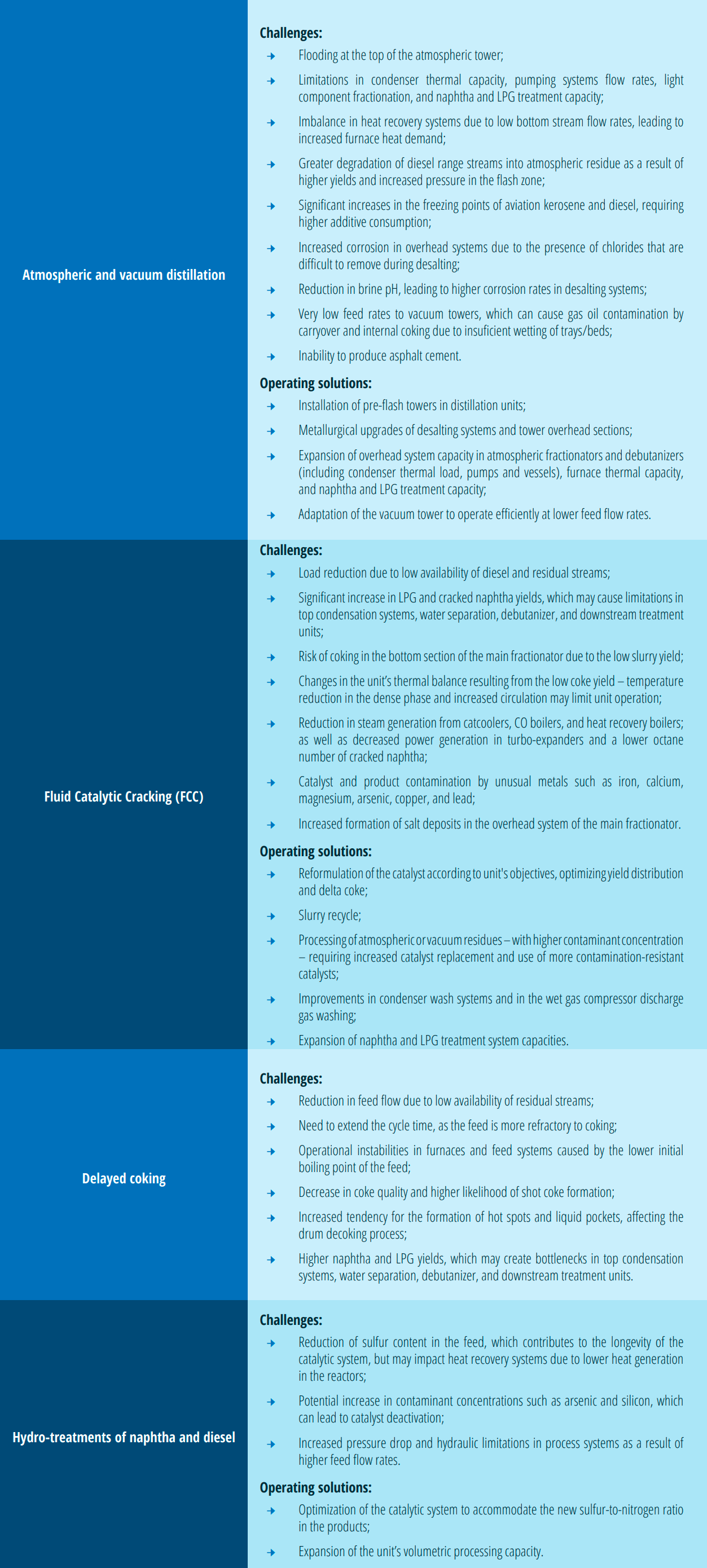

The main challenges and corresponding solutions for processing lighter crude feeds are described below.

What did you make of the publication?