Diesel oil is one of the most commonly used fuels in the world, being used in cars, large vehicles and generators, for example. It is a fuel suitable for diesel cycle engines, and since this kind of engine does not require an ignition source, the features of the fuel to be used should enable its immediate combustion when it contacts the heated air found in the combustion chamber interior. This ease to ignite is measured by the Cetane Number.

Cetane can be assessed on a special motor (cetane number) or in laboratory equipment that determine the ignition delay (derived cetane number) and indirectly measures the period of time elapsed between the fuel injection and the beginning of the burning.

The standards are mixtures of known volumetric fractions of cetane – n-hexadecane – (cetane 100) and a-metil-naftaleno (cetano 0). The cetane number represents the cetane volumetric percent in a mixture with a-metil-naftaleno which would have the same burning feature of the tested fuel.

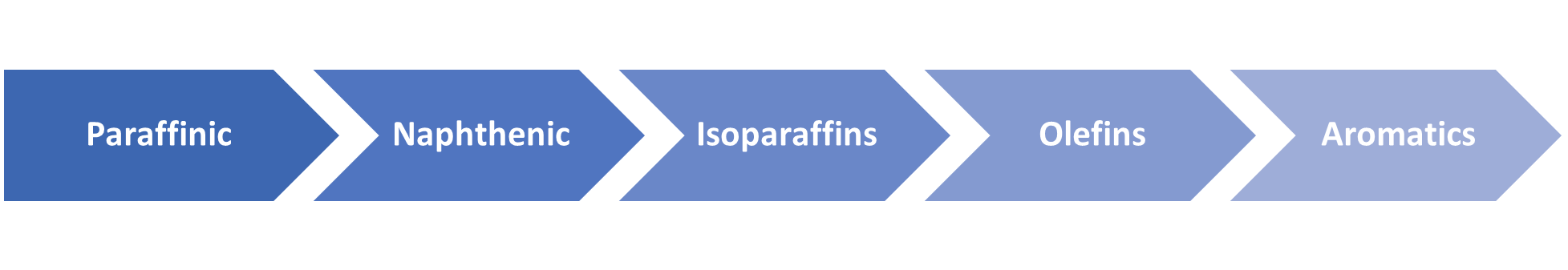

Diesel cetane depends on the hydrocarbon species present in the fuel. Generally, it varies with the hydrocarbon types in the following order:

To a certain point, cetane also increases with molecular weight since the hydrocarbon self-ignition temperature is reduced with the increase in molecular size, however, very heavy hydrocarbons do not atomize well and this causes delay in the beginning of the burning.

The Diesel Cycle is more efficient than the Otto Cycle (of gasoline engines) because of its high compression rate. The higher the compression rate of a diesel engine the higher its efficiency, but also the higher the damage potential in case the fuel is not adequately burned, that is why the more updated diesel engines (EURO 5 and EURO 6) require a higher Cetane fuel, with lower density and lower sulfur, which can limit the incorporation of certain components into the mixture.

Each stream that makes diesel has a different composition and therefore a different cetane, depending on its origin:

- Direct distillation: heavy naphtha (smaller); kerosene (intermediate); light diesel (higher); heavy diesel (higher);

- Catalytic Cracking: cracked naphtha and LCO (smaller);

- Hydrocracking: heavy naphtha (smaller); kerosene, diesel (higher);

- Delayed Coking: diesel (smaller).

The petroleum index also influences the cetane of the streams compounding diesel, the more paraffinic the crude, the best the Cetane, however, the use of a highly paraffinic crude could affect negatively other specifications, such as the freezing point.

LCO and heavy cracked naphtha:

These are low-cetane diesel components, the incorporation of which into the diesel mixture (after hydrotreatment) brings the following advantages:

- Drop in Plugging Point and rise in lubricity;

- Improved heat generation in the hydrotreating reactors, which boosts the unit internal heat recovery, it being possible to drop the fuel gas consumption in the heating furnaces of the unit products;

- Improved volumetric yield of diesel in the refinery;

- Reduction of fuel oil generation in the refinery.

By making adjustments in the FCC unit it is possible to improve both the yield and the LCO and heavy cracked naphtha cetane, which can contribute for the incorporation of these products into the diesel mixture. A few suggested adjustments are:

- Reduction in reaction temperature;

- Increase in feed temperature for circulation reduction;

- Change in catalyst system formulation for selectivity modulation and hydrogen transfer reactions.

The FCC S.A. Technical team is available to aid its customers in the optimization of their units.

What did you make of the publication?