1. Introduction

Within a refining scheme each unit has its own role, which was studied and planned to fulfill an objective in the refinery, contributing with its share for the end products’ quality or the compliance with legal requirements. Among feedstocks, products and effluents, several streams are conveyed from one unit to the other until leaving the refinery in their final form. Each unit influences the other ones in several ways, and since the goal is optimizing not only one unit, but the refinery as a whole, understanding what a setting or disturb in an unit causes to the other ones is part of the basic knowledge of a process engineer working in refining processes.

In this article we will briefly address some of the main influences applied by other refining units on the FCC and which influences the FCC exerts on them by focusing on a few units present in the most common refining schemes.

2. Diesel hydrotreating

Although light cycle oil and heavy cracked naphtha are products in the diesel range, due to their characteristics they cannot be incorporated directly into the pool in significant amounts, especially as refineries face the ever more stringent specifications of this fuel. To be harnessed as diesel, these products must be hydrotreated.

Contrary to what is seen with cracked naphtha, in many cases the refineries do not owe captive hydrotreating units for diesel streams originated from catalytic cracking, and these streams may be treated along with streams originating from other units, such as distillation and delayed coking. In these units the diesel stream to be treated is 100% in the liquid phase.

When compared to the atmospheric distillation’s diesel, LCO (as well as heavy cracked naphtha) shows higher concentration of aromatic, olefinic, nitrogen and sulfur compounds, which renders its treatment more complex, mainly when the objective is the production of ultralow sulfur diesel (ULSD). LCO has a low cetane number, high sulfur and high density, these factors limiting its incorporation into the diesel pool, in addition to the presence of polynuclear aromatics which intervene in the product color. The presence of nitrogen compounds also affects product stability. On the other hand, the incorporation of products originating from catalytic cracking can improve characteristics such as cold filter plugging point and, due to its normally lower final boiling point, contribute to a volume increase in the produced diesel without affecting distillation specifications. Similarly to what is seen with cracked naphtha, these FCC products should not be in contact with oxygen before being conveyed to the hydrotreating unit because of the possibility of gums formation in tanks and reactor beds. Several units further include an exclusive filtering system for unstable products.

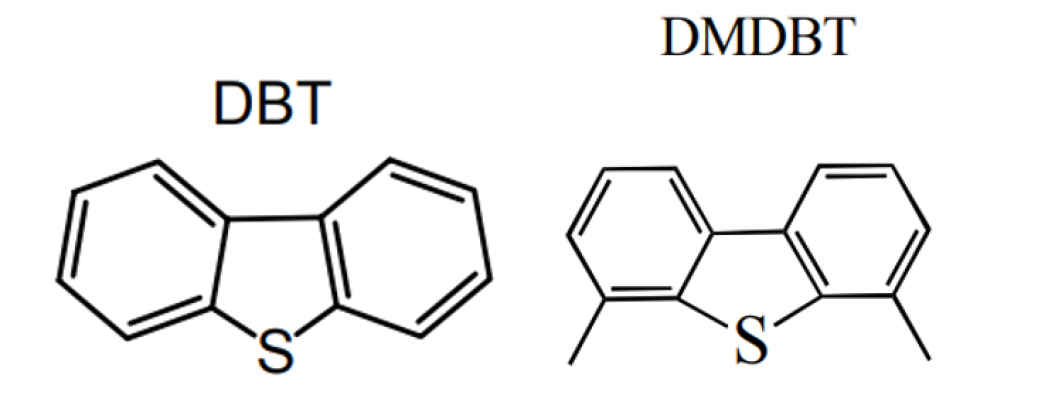

The choice of the hydrotreating unit’s catalytic system is crucial for adequate LCO treatment and should be designed in agreement with the goals of each refinery. Some of the sulfur species present in LCO are more refractory to desulfurization because of steric hindrance and their removal requires hydrogenation reactions which transform polyaromatics into monoaromatics to then enable sulfur removal. This way, more severe reaction conditions are required, at higher WABTs (Weighted Average Bed Temperature – reaction temperature parameter) and higher hydrogen partial pressure, as well as a catalyst with higher hydrogenation activity and sometimes more than one reactor arranged in series.

Figure 1 - Dibenzothiophene x dimethyl-dibenzothiophene: steric hindrance requires higher severity

The presence of polyaromatics and other unstable components raises the need to make use of protection beds to inhibit coke deposition at the top of the reactor, also requiring higher hydrogen availability for hydrogenation reactions to correct the product’s color.

The organic nitrogen present in this stream inhibits hydrodesulfurization reactions, therefore the catalytic system should also perform hydrodenitrogenation reactions efficiently to enable attainment of ultralow sulfur values in treated diesel. In these cases, the catalytic system should be designed to increase the efficiency of nitrogen removal reactions to enable deep desulfurization to occur. The presence of organic nitrogen also affects negatively the diesel’s stability and color, its removal being important for these parameters. The exothermic characteristics of the reactions require the existence of physical systems and procedures to enable temperature control in the reactors, avoiding runaways that can lead to the undesired production of light products (cracking) and can also be harmful to the unit.

The fact that LCO causes the temperature to increase in the reactor effluent as a result from an increase of exothermic reactions can be advantageous for some units, since in many of them there is a heat exchanger that uses this effluent to pre-heat the feed. With a warmer feed the unit saves part of the fuel which would be used in the unit’s furnace for final heating before the reactors.

LCO’s quality affects the diesel hydrotreating unit in several ways, impacting mainly the extension of the period between turnarounds and the efficiency of sulfur removal, that is why in order to process this product (specially near the end of run) a few adjustments in the FCC unit can be required:

2.1. Fractionation

In terms of fractionation, the final boiling point is the most critical variable since, similarly as what happens with naphtha, it defines the amount and the species of sulfur compounds that are present, as well as the amount of nitrogen compounds and polyaromatics. A higher or lower concentration of hydrotreating refractory species is one of the constraints for the volume of LCO and/or heavy naphtha that can be treated, the other main constraint being the maximum reactor temperature.

Fractions of LCO with final boiling points higher than 310°C contain sulfurate hydrocarbons that are resistant to hydrodesulfurization, such as methyl-, dimethyl- and trimethyl-dibenzothiophenes, which require more severe conditions for sulfur removal, representing a potential problem for units operating under milder reaction conditions to reach ultra-low sulfur diesel specifications. The presence of nitrogen compounds which are also refractory to hydrotreatment, such as alkylated indoles and carbazoles, can affect the quality of the final diesel. Even for medium and high severity units, it is important to know that the higher the concentration of these refractory compounds the lower the lifespan of the hydrotreating catalysts, therefore the correct management of LCO quality is an investment in increasing the catalyst’s longevity.

On the other hand, fractionating the LCO to a final boiling point close to 310°C can be a problem for the FCC unit due to the increase in slurry generation and the additional heat duty required to sufficiently cool the main fractionator to reach this end point. If the unit produces slurry with the objective to sell it to the chemical industry as feedstock for the production of carbon black, this product’s quality can be thoroughly affected by LCO degradation.

Generally, reactors working under milder conditions or those that have difficulties in bed temperature control can better tolerate heavy cracked naphtha incorporation in spite of LCO incorporation, however, not all of FCC units have the hardware to withdraw it and, as already discussed in the chapter on cracked naphtha’s HDS, such withdrawal affects the main fractionator’s efficiency. HCO withdrawal can also be an alternative to enable a reduction in LCO’s final boiling point without overburdening the main fractionator’s bottoms system, however it also requires suitable hardware.

Fractionation influences the FCC units’ LCO (and heavy naphtha) volumetric yield and can be modified as a function of the refinery’s capacity for treating the cracked products in the diesel range. Refineries designed to favor diesel maximization usually can incorporate all the available LCO, and may deliberately reduce the cracked naphtha’s final boiling point to increase this product’s (or heavy naphtha’s) yield. On the other hand, in case the refinery does not have the capacity to incorporate all the LCO to diesel, the tendency is to maximize the production of cracked naphtha, since the LCO surplus is normally used as fuel oil diluent.

Special attention should be directed to LCO when salt-dispersing additives are used in the main fractionator, due to the possible presence of chlorides in this stream. This contaminant’s concentration should be analyzed frequently and the hydrotreating unit should be prepared to tolerate the presence of chlorine.

2.2. Operating conditions

Operating FCC under higher or lower severity also impacts LCO quality. Conditions that favor a conversion increase, in addition to reducing LCO yield (which is considered non-converted fraction), also increase the aromatics’ concentration in this stream, affecting characteristics such as cetane and density and rendering this stream more refractory to hydrotreating. The main variables that influence LCO’s quality are:

- Reaction Temperature: the higher it is, the lower the LCO yield and the worse its quality;

- Dense phase and feed temperatures: the higher these temperatures, the lower the catalyst circulation, the higher the LCO yield and the better its quality.

- Catalytic System: the more active it is, the lower the yield and the worse the LCO’s quality.

2.3. Influences of diesel hydrotreating on FCC

Further than influencing operating conditions and fractionation in the FCC unit, the diesel hydrotreating unit can also affect the FCC’s feed flowrate when there is an excessive LCO production, mainly near the end of run, since the surplus has to be directed to the production of lower value petroleum products.

Another potential influence of these units on the FCC is the destination of product streams to this unit, especially a stream known as wild naphtha. Hydrocracking reactions that generate light hydrocarbons on fuel gas, LPG and naphtha ranges occur in hydrotreating units, mainly on those working under high severity conditions. While the fuel gas and LPG streams are generally treated and conveyed to the refinery fuel gas system, the naphtha should have its destination carefully thought by the refinery since its RVP andH2S concentration are high, hence the name wild naphtha. In many refineries this naphtha cannot be directly sent to tanks, being preferably directed to the distillation and coke units, but frequently conveyed to the main fractionator’s overhead drum. Although this naphtha’s flowrate is usually low, it affects the unit’s mass balance, so it should be taken into account for corrections, and its paraffinic nature affects octane numbers negatively.

2.4. Summary

LCO’s and heavy cracked naphtha’s qualities have direct influences on the hydrotreating units’ catalysts lifespans and on their sulfur removal efficiency, the main ones being:

- The choice of the catalytic system;

- WABT;

- Catalyst lifespan;

- Hydrotreated diesel’s density and cetane number;

- Hydrogen consumption;

- Unit’s energy consumption

The main adjustments that may be necessary on the FCC unit with the objective of maintaining adequate volume and feed quality parameters for diesel hydrotreatment units are:

- Catalytic system;

- Withdrawal of heavy cracked naphtha;

- LCO fractionation;

- Unit’s feed flowrate;

- Wild naphtha processing.

- Reaction , dense phase and feed temperatures:

3. Delayed coking unit

A delayed coking unit (DCU) carries out thermal cracking of residual streams on the fuel oil range, converting those into fuel gas, liquid products and coke, with product yields concentrated on the diesel range. It is one of the most commonly employed alternatives when it comes to minimizing the refinery’s fuel oil production and maximizing the volume of produced diesel. The most common coking unit feeds are:

- Atmospheric residue;

- Vacuum residue;

- Asphaltic residue;

- FCC’s slurry oil.

Since this is a process for thermally cracking residual streams, the DCU’s liquid products are generally high in sulfur and olefinic compounds, including diolefins in considerable concentrations, which renders them unstable, prone to oxidation and polymerization reactions. Additionally, the marked presence of heteroatoms such as nitrogen and oxygen in gasoline and diesel range products leads to the need of deeply hydrotreating them before their incorporation into refinery products. The presence of high concentrations of aromatic and polyaromatic compounds, as well as the presence of contaminants such as silicon, arsenic and copper also characterize these products.

3.1. DCU influence on FCC

Among the delayed coking products, generally the heavy coker gas oil, a product on the fuel oil range, is conveyed to the FCC’s feedstock, which can also receive light coker gas oil and coker naphtha; normally these two later streams are processed in the riser only when their respective hydrotreatments are unavailable.

DCU’s settings, such as furnace temperature, batch time and fractionation can influence the quality of products conveyed to the FCC’s feedstock in terms of different concentrations of aromatic hydrocarbons, sulfur and basic nitrogen.

3.2. Heavy coker gas oil

Among the DCU products, heavy coker gas oil is the most commonly incorporated to the FCC’s feedstock. In case it is not previously hydrotreated, this stream has high density, high aromatics content, low metal content and up to eight times more basic nitrogen than vacuum gasoil. It is, therefore, highly refractory to catalytic cracking, since the FCC does not convert aromatic compounds and that basic nitrogen temporarily deactivates the catalyst’s active sites, reducing conversion as a whole, as it inhibits catalytic cracking reactions. A few experiments carried out with pure coker gas oils obtained conversions around 50%.

Additionally, as it contains polyaromatic species, whenever heavy coker gas oil is processed the formation of compounds originating from polyaromatics’ condensation reactions increases the non-catalytic coke yield and the presence of this coke does not allow access of other compounds to the catalyst’s active sites, thus reducing total conversion, which results in a higher coke factor (coke yield weighted by conversion). In summary, for the same conversion, coker gas oils-containing feedstocks have a higher coke yield than feeds without coker gas oils due to the polyaromatics condensation characteristic of those feedstocks (and which does not always appear as a higher carbon residue in routine analyses).

Those effects are especially relevant in units limited by air availability for the converter, which tend to work at isocoke conditions, since in these cases the conversion reduction caused by the processing of this kind of feedstock cannot be compensated by increasing the rection temperature, since the coke yield would increase, which increases the air demand.

The higher coke production caused by processing this kind of feedstock can also lead to an increase in dense phase temperature and consequent reduction in catalyst circulation, which causes catalytic conversion to decrease and thermal conversion to rise, resulting in higher olefinicity in products and higher fuel gas production.

High accessibility catalysts, suitable for residual feeds, with balanced acidity to reduce coke formation, are important to maximize conversion whenever non-hydrotreated coker gas oil is processed in FCC. The adjustment of operating conditions and the unit’s feed flowrate may be necessary to outweigh the effects of the lower conversion and higher coke generation during heavy coker gas oil processing, such as for example increasing the reaction temperature, increase in feed temperature and even the reduction of the feed flowrate.

3.3. Light coker gas oil

Light coker gas oil is a diesel range stream, with high aromatics content (low cetane) and high basic nitrogen content. In a refinery it is preferably hydrotreated to be incorporated into the diesel pool and generally it is sent directly to the HDT unit, since the contact of this stream with oxygen can render its hydrotreatment non-viable. Usually, this stream is only conveyed to FCC units if the hydrotreating unit is unavailable.

This stream is highly refractory to catalytic cracking and when processed in the FCC unit it causes a reduction in the conversion, not only because a considerable portion of this stream does not react and exits as LCO, but also because the high basic nitrogen concentration temporarily deactivates the catalyst’s active sites, reducing the conversion as a whole. Adjustments in the FCC’s reaction temperature may be required to readequate the conversion and LCO’s withdrawal capacity should be evaluated, since the increase in this product’s yield is predicted and in the case there is no capacity for full LCO withdrawal it can be degraded into slurry oil, affecting its quality.

3.4. Coker naphtha

The naphtha produced from the delayed coking process is rich in olefins, diolefins, aromatics and sulfur compounds, and can also contain nitrogen and silica. The high diolefin concentration (around 5% of the total olefins) makes this product unstable and especially in the presence of oxygen it tends to form gums, which precludes its direct addition to gasoline pools, requiring direct processing in hydrotreating units, avoiding tankage.

In case coker naphtha hydrotreating units are unavailable, one of the ways to deal with this product is to process it in the FCC unit’s riser, either admixing it to the feed (generally heavy coker naphtha) or injecting it in the riser’s bottom, before the main feed inlet. In the same way as other kinds of naphtha, when injected in the riser , coker naphtha increases catalyst circulation since upon vaporizing it absorbs heat and hot catalyst flow must be raised to keep the desired reaction temperature.

Whenever it is FCC-processed, most of the coker naphtha will be recovered as cracked naphtha. Generally, diolefins tend to form coke on FCC catalyst, while olefins tend to undergo catalytic cracking then forming LPG-range lighter olefins and aromatic hydrocarbons do not undergo catalytic cracking. Due to the coke formation on the catalyst, coker naphtha injection may cause a reduction in conversion since the heavier feedstock’s access to active sites would be impaired.

Depending on the catalytic system and operating conditions, it is possible to increase or to reduce the LPG yield resulting from coker naphtha processing. Highly acidic catalysts will increase LPG production and their olefinicity, especially when dealing with high rection temperatures , while moderate acidity catalysts and low reaction temperatures will favor naphtha yield.

Generally, since coker naphtha is a high sulfur concentrated stream, whenever coker naphtha is FCC-processed the tendency is to increase the cracked naphtha’s sulfur content.

3.5. FCC influence on DCU

The main FCC influence on the DCU is when slurry oil is sent to the DCU as feedstock, since this stream can modify the quality of the produced coke. Special care should be provided to control the amount of FCC catalyst present in in the slurry, known as ashes, since the presence of this catalyst reduces the quality and value of the obtained coke, that is why in general the slurry oil is only sent to the delayed coking unit after an ash-removal treatment.

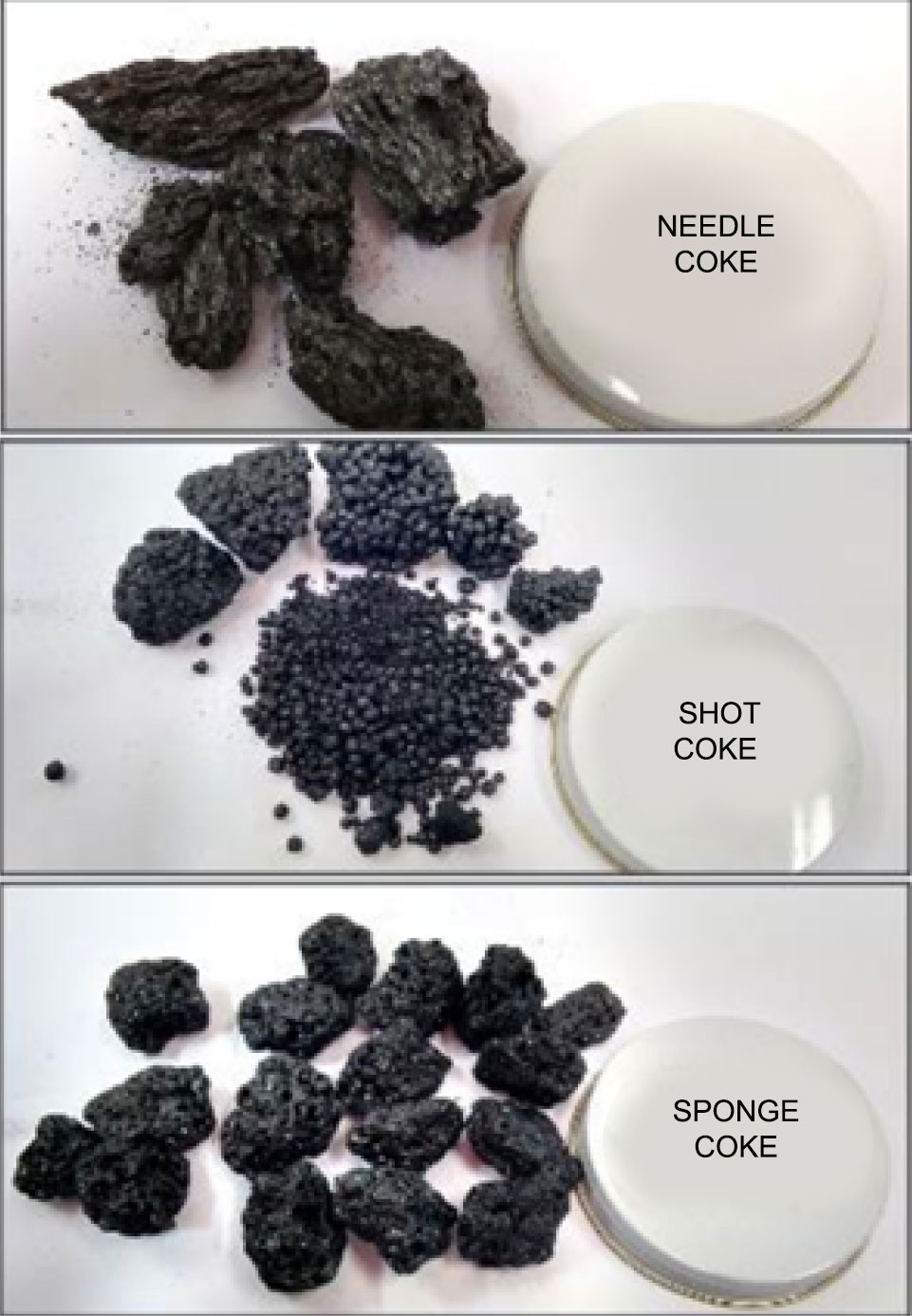

The coke produced by a DCU can have different qualities and according to its properties its selling price varies. This quality is defined by feedstock’s quality and the unit’s operating conditions, being defined by its content of sulfur, ashes, metals, volatile materials, hardness and crystallinity.

Needle coke is the most valuable product, used for obtaining graphite electrodes for the steel industry. This coke is obtained from feedstocks that are rich in heavy aromatics with low sulfur, metals, resins and asphaltenes. The most common raw material for producing this kind of coke is FCC’s slurry oil. That is why, for producing this kind of coke, the quality of the slurry is important: ensuring fair separation from the LCO (the DCU does not handle well light feeds), suitable severity so the slurry has a high concentration of heavy aromatics and a good separation of the entrained catalyst to control the ash content, are essential.

There are two other kinds of coke: sponge coke and shot coke. Generally shot coke production is avoided, since in addition to being the less valuable kind it can cause operating problems during the decoking operation, as it forms agglomerates which difficult the coking drums’ cooling process, leading to the possibility of the occurrence of hot spots. When decoking water reaches hot spots created by shot coke agglomerations it can vaporize suddenly, causing from abnormal particulate emissions to damage to coke drums.

Units that do not produce needle coke usually aim to produce sponge coke, which depending on characteristics such as its sulfur content and metals can be utilized for metallurgical applications, for manufacturing carbon anodes for the aluminum industries and electrodes for the steel industry, or as fuel. After ash removal, FCC’s slurry can be utilized by refineries to improve the quality of produced coke, increasing the content of heavy aromatics and diluting asphaltenes and resins in the DCU’s feedstock, which can hinder shot coke production.

Figure 2 – Different kinds of coke Source (7)

The slurry oil’s ash content can also affect, in addition to coke quality, both the DCU feed’s pumping systems, mainly by erosion, and the main fractionator, as a result of deposits.

3.6. Shared units

FCC’s and DCU’s product treating sections are rather similar. Treatments for products such as fuel gas, LPG, naphtha and diesel as well as by-product’s treatments such as sour waters and acid gases can be shared. Amine treating units, regenerative caustic treatment, hydrotreatments, sulfur recovery units and sour waters treatment units are the main examples of shared units.

Such synergy can be rather beneficial to the refinery, especially in terms of hardware economy, but it also brings the risk that disturbances in one unit may intervene in the quality of the whole production (in case of products) or impose limits to the other unit’s feed rates and/or operating conditions. Whenever shared treatment units are planned, it is important to consider sufficient operating flexibility, so the treatment unit continues to operate smoothly when the DCU or the FCC are out, and in case of disturbs it is important to provide mechanisms that enable the diversion of streams from one or other unit, minimizing the amount of off-spec products.

3.7. Summary

As a function of the DCU’s interference on FCC’s feed quality, which can reduce the unit’s conversion and increase the productions of coke and fuel gas, a few FCC adjustments can be required when processing streams originating from DCU:

- The catalyst used in the unit:

- Reaction and feed temperatures;

- Fractionation and LCO withdrawal;

- Unit feed flowrate.

On its turn, when processing slurry from the FCC unit, the DCU tends to produce a better-quality coke, however it can suffer from catalyst deposits and erosion. To secure a good DCU operation, the FCC may have to make the some adjustments:

- Slurry oil fractionation;

- Increase severity (increase in reaction temperature and catalyst circulation);

- Control slurry oil’s ash content.

4. References

- Alan Kramer, Avoiding the Low Sulfur Diet – New Catalytic Ways to Cost-Effectively Reduce Product Sulfur and SOx Emissions – NPRA Annual Meeting 2011.

- Refining Overview - Petroleum, Products and Processes, AIChE, 2000.

- Fluid Catalytic Cracking: Science and Technology. A Magee, J.S., A Mitchell, M.M., 1993, Elsevier Science.

- Andrea Battiston - Kinetic engine drives catalyst development - Development of a NiMo catalyst for medium-to-high and high pressure middle distillates hydrotreating - https://www.digitalrefining.com/article/1001243/kinetic-engine-drives-catalyst-development.

- Wang, Gang & Liu, Yindong & Wang, Xiaoqin & Xu, Chunming & Gao, Jinsen. (2009). Studies on the Catalytic Cracking Performance of Coker Gas Oil. Energy & Fuels - ENERG FUEL. 23. 10.1021/ef801046t.

- Roberto Palos, Alazne Gutiérrez, María L. Fernández, David Trueba, Javier Bilbao, José M. Arandes, Upgrading of heavy coker naphtha by means of catalytic cracking in refinery FCC unit, Fuel Processing Technology, Volume 205,2020, 106454, ISSN 0378-3820, https://doi.org/10.1016/j.fuproc.2020.106454.

- UPGRADING OF DELAYED COKER LIGHT NAPHTHA IN A CRUDE OIL REFINERY Attila Lengyel1 , Szabolcs Magyar1 , Jeno Hancsók2* Petroleum & Coal ISSN 1337-7027.

- Petrobras - COQUE VERDE DE PETRÓLEO - Informações Técnicas (versão dez/19) - https://petrobras.com.br/documents/2677942/3190768/Coque-InformacoesTecnicas.pdf.

- Zhang, Haiping, Lin, Hongfei and Zheng, Ying. “Hydrotreatment of Light Cycle Oil Over a Dispersed MoS2 Catalyst” International Journal of Chemical Reactor Engineering, vol. 14, no. 3, 2016, pp. 703-711. https://doi.org/10.1515/ijcre-2015-0112.

What did you make of the publication?